Sci/tech

PFBR proves India's capabilities in advanced nuclear sciences, engineering

New Delhi, March 15 (IANS) It is heartening that Prime Minister Narendra Modi recently visited Kalpakkam to witness the start of fuel loading in the Prototype Fast Breeder Reactor (PFBR). Commencement of fuel loading is a major milestone for PFBR, indicating that all major sodium and water loops are functional, and that all static and dynamic equipment are in healthy state.

PFBR, built by Bharatiya Nabhikiya Vidyut Nigam Limited (BHAVINI), is currently in the final stage of commissioning. PFBR marks the commencement of the second of the three-stage commercial nuclear power production, planned by Homi Jahagir Bhabha way back in 1950.

This is an occasion for the entire Department of Atomic Energy (DAE) fraternity — and for that matter for every Indian — to be proud of the combined achievement of the BHAVINI and Indira Gandhi Centre for Atomic Research (IGCAR) teams.

In October 2004, then Prime Minister Manmohan Singh had marked the occasion by starting concreting of PFBR Raft.

This highly complex reactor is now nearing completion.

Visits of Prime Ministers, President (Abdul Kalam), several Union Ministers, Director Generals of International Atomic Energy Agency (IAEA) (Mohamed ElBaradei and Yukiya Amano), Deputy Director Generals of IAEA, several other international dignitaries and ambassadors, Parliamentary committees, many Padma Awardee Scientists and others to PFBR in the past, is a testimony the importance of PFBR in the global scenario.

The fast breeder reactor technology has the potential to generate more nuclear fuel (plutonium) than it consumes. This is achieved by using fast neutrons to convert fertile material (depleted uranium) into fissile material. The PFBR contributes to India’s efforts to achieve energy security by efficiently utilising its indigenous uranium and abundant resources of thorium.

PFBR is a stepping stone to move from U235 fuel to U233 fuel. PFBR is designed and constructed entirely in India, showcasing the country’s capability in advanced nuclear sciences and engineering, and close fuel cycle.

The PFBR is a significant achievement in India’s indigenous nuclear reactor technology capabilities.

For concerted efforts to make fast reactors commercially viable, eminent scientist Anil Kakodkar initiated to launch the fast breeder reactors through a new company, BHAVINI. Late Baldeo Raj, then Director of IGCAR, and his team played a leading role in plant and equipment design, testing and qualification of equipment. IGCAR, in close proximity to PFBR construction site, has provided multi disciplinary support to PFBR and trained PFBR operation personnel in Fast Breeder Test Reactor (FBTR).

The PFBR project has brought several laurels for India, contributing to the country’s nuclear energy programme and technological prowess. Achievements and accolades associated with the PFBR encompass Indigenous technology development and demonstrate the country’s capability to design, construct, and operate advanced nuclear reactors without relying on foreign assistance.

PFBR involves cutting-edge research and innovation in nuclear reactor technology. It fosters advancements in reactor design, materials science, safety analysis, and operational efficiency.

The PFBR project has facilitated collaboration with international partners, including knowledge exchange, and research cooperation.

The PFBR project has stimulated economic growth through investments in infrastructure, development of novel manufacturing technologies and creation of highly skilled workforce. A robust nuclear energy ecosystem in India, created by PFBR, harmonised contributions from R&D organisations, researchers, material scientists, intricate equipment manufacturers and highly skilled installation and commissioning teams.

Handling, storage and transfer of 1,950 metric tonne sodium without spilling a single drop, speaks volumes about competence of fast reactor teams at Kalpakkam. India’s achievements in fast breeder technology showcases the country’s potential to become global leader in thorium technology landscape.

Fast breeder reactors operate under extreme conditions of temperature, pressure, and radiation, requiring advanced materials that can withstand these conditions. Developing and qualifying materials for reactor components, including structural materials, cladding, and fuel elements, have been a technological challenge.

The Indian industry has played a significant role in producing materials to stringent specifications and manufacturing and fabrication of equipment for the PFBR project. Almost all the materials for the fabrication of PFBR have been manufactured by Indian companies.

Indian engineering firms have provided design, engineering, and consultancy services for this project. This includes the development of detailed engineering designs, safety analyses, and quality control measures. Young PFBR team took up challenging construction, commissioning and quality assurance responsibilities.

Indian thermal neutron reactors built by Nuclear Power Corporation of India Limited had increased the quality production capabilities of Indian industries over the decades. PFBR required enhanced competence from industries for its equipment which are much larger in dimension and required far more stringent specification and tolerance control.

Large thin walled Safety vessel, Main vessel and Inner vessel required stringent safety design and fabrication capabilities, have been fabricated by Larsen and Toubro and BHEL at PFBR construction site, since these were too large to be transported by road.

Never in the past were such large thin walled vessels fabricated in India. Thin walled Inner vessel made by BHEL, required critical control of dimensional tolerances in complex geometry.

It is worthwhile to mention that the experience of Safety and Main Vessel fabrication for PFBR provided an opportunity to Larsen and Toubro to fabricate yet another large size thin walled vessel at ITER (Fusion reactor project at France, a project to create fusion in a large tokamak and create temperatures ten times the temperature of the Sun).

The cryostat, a stainless steel vacuum pressure vessel weighing 3,850 tonnes and of 30 metres in diameter is the largest vessel ever made in the world. It has glorified India’s manufacturing capabilities before the world.

Kirloskar Brothers Limited (KBL) came forward to take on the highly challenging task of design and manufacture of primary and secondary sodium pumps. They have to circulate liquid sodium at temperatures over 500 degrees. Primary sodium pump has an 11 metre long shaft. The secondary sodium pump has hydrodynamic bearings. Since the pumps operate in a sodium environment, they have to be almost maintenance free.

It took knowledge, skills and courage by KBL team to accept the order for these pumps. KBL has demonstrated that Indian industries can take up any challenge.

MTAR Technologies undertook the manufacture of inclined fuel transfer machine and reactor top control plug. WalchandNagar Industries manufactured large sodium-to-sodium and sodium-to-air heat exchangers. Sodium-to-water heat exchanger/steam generators were made by Larsen and Toubro. All these entities created specialised clean room facilities to undertake manufacture of critical PFBR equipment.

Tata Consulting Engineers (TCE) supported PFBR in design details and Gammon India undertook civil and structural works requiring great precision. Power Island equipment were manufactured by BHEL.

Various units of Department of Atomic Energy including Nuclear Fuel Complex, Electronics Corporation of India Ltd, Heavy Water Board etc took up challenging responsibilities. IGCAR manufactured many critical equipment in its workshop and dedicated many of its labs and test loops for testing and qualification for PFBR equipment.

PFBR had to pass through some rough patches during its construction and commissioning.

The Tsunami on December 26, 2004, had destroyed the project completely. Restart of the construction required a fresh safety review involving expertise of various centres of knowledge in geology, seismology, oceanography, meteorology etc. Design changes and raising the garage level of the PFBR had an impact on cost and time of the project.

The Fukushima accident in Japan on March 11, 2011 required every nuclear facility in the world — under construction or in operation — to have a fresh review of safety in the background of new knowledge that came forth by the Fukushima accident. This, too, required back fitting of a few new features in PFBR, and thus impacted the cost and time.

It has been noted that wherever ambitious mega projects to create new technologies are launched, despite the best risk management features in place, challenges beyond expectation are faced during construction and commissioning. These, beyond planning events, have resulted in delays and cost escalation.

Despite best planning, best brains involved, extensive testing and qualification programmes, and most meticulous construction and commissioning practices adopted, many first of this type of projects in the world have experienced issues beyond original risk evaluation. ITER, France is one such example.

In PFBR the design, equipment fabrication and construction have been undertaken simultaneously. To put an end to design refinements, DAE had taken one of the most appropriate decisions to launch PFBR in October 2003, and asked designers, equipment manufacturers, construction personnel to work together to manage the complex technology and establish safety protocols.

It may also be appropriate to mention that for the fast breeder reactors, the regulatory framework and safety principles were not fully developed by the Atomic Energy Regulatory Board when the PFBR was launched. Many of the safety rules were prepared parallelly during construction of PFBR. This, too, had little impact on pace of construction.

Fast reactors are extremely complex. Presence of a huge amount of sodium adds to the complexities in design, construction, commissioning and maintenance.

Fast breeder power reactor programmes were launched only by four countries. These are France, Japan , Russia and India. France and Japan have shut down their reactors due to sodium leak and associated fire. Both France and Japan and are currently going slow with their plans till generation four features are implemented. Russia is the only country operating the fast breeder reactor. India has introduced many generation four features in PFBR after the Fukushima accident, and is pursuing the fast breeder reactor programme with robust design and technological backbone existing now in the country.

In 2003, when the PFBR project was launched by BHAVINI, only a few experienced personnel were available on deputation from IGCAR, who had knowledge of fast breeder reactor design and operation of FBTR. BHAVINI had to appoint fresh engineering graduates and initiate a major training and qualification programme for the freshers to manage the complex and first of its type fast reactor technology for PFBR. This was an initial hiccup which was later fixed.

IGCAR and other units of DAE have been involved in skill development, training and qualification programmes for personnel working in the PFBR project. The training in FBTR includes providing specialised skills and preparing the operation teams to get PFBR operation licence from AERB.

As time passed, BHAVINI engineers got recognised as one of the most competent, committed and hard working professionals.

(Dr Prabhat Kumar is former CMD of BHAVINI.)

–IANS

Prabhat Kumar/kvd

Sci/tech

21.67 lakh new workers enrolled in ESIC scheme in June, 10.58 lakh young employees

New Delhi, Aug 22 (IANS) The Centre on Thursday informed that 21.67 lakh new employees were enrolled under the ESIC scheme in June, ensuring social security to more workers.

The year-on-year (YoY) analysis showed a growth of 7 per cent in net registrations compared to June 2023.

As per provisional payroll data of ESIC (Employees’ State Insurance Corporation), 10.58 lakh young employees up to the age group of 25 years constitute new registrations.

According to the data, 13,483 new establishments were registered under the ESIC scheme in June.

“Through the data, it is noticeable that out of the total 21.67 lakh employees added during the month, 10.58 lakh employees amounting to around 49 per cent of the total registrations belong to the age group of up to 25 years,” according to the government.

The gender-wise analysis of the payroll data indicates that net enrolment of female members has been 4.32 lakh in June.

Besides, a total of 55 transgender employees have also got registered under the ESI scheme in June “which attests the commitment of ESIC to deliver its benefits to every section of the society”.

In May, 23.05 lakh new employees were added in the ESIC scheme, which represented a growth of 14 per cent in net registrations compared to the same month last year.

The data showed that out of the total 23.05 lakh employees added during the month, 11.15 lakh employees amounting to around 48.37 per cent of the total registrations belong to the age group of up to 25 years.

The net enrolment of female members was 4.47 lakh in May. In April, 16.47 lakh new employees were added out of which close to half are youngsters aged up to 25 years.

A total of 60 transgender employees were registered under the ESIC scheme during the month of May.

–IANS

na/

Sci/tech

Sunita Williams’ fate hangs in balance as NASA weighs return options

Washington, Aug 22 (IANS) NASA astronauts Sunita Williams and Butch Wilmore arrived at the International Space Station (ISS) on June 6 and more than two and a half months later, their fate hang in balance as NASA mulls several options which can delay their return to earth to even February next year.

The astronauts left for the orbiting laboratory on June 6 aboard the Boeing Starliner after lifting off on June 5 from Space Launch Complex-41 at Cape Canaveral Space Force Station in Florida in the US.

Originally slated to return within a week, their stay could now potentially stretch to over eight months owing to serious issues with Starliner.

According to the US space agency, if it decides to return Starliner uncrewed, Sunita and Butch would remain aboard station until late February 2025.

NASA would replan the agency’s SpaceX Crew-9 mission by launching only two crew members instead of four in late September. The two stuck astronauts would then return to Earth after the regularly scheduled Crew-9 increment early next year.

According to reports, it Elon Musk-run SpaceX is tasked with the return of Sunita and Butch, it will a major embarrassment for its rival Boeing.

At a press event, NASA officials said they have reached a point where, in the last week in August, “we really should be making a call, if not sooner”.

Bowersox said the astronauts were “making the best” of their extra time aboard the ISS “but I’m sure they’re eager for a decision, just like the rest of us.”

The US space agency is under tremendous pressure to make a quick yet safe decision regarding the astronauts’ return.

According to the US space agency, no final decisions have been made.

“NASA continues to evaluate all options as it learns more about Starliner’s propulsion system. Butch and Suni may return home aboard Starliner, or they could come back as part of the agency’s SpaceX Crew-9 mission early next year,” it said.

The International Space Station is “well-stocked with everything the crew needs, including food, water, clothing, and oxygen”.

Recently, a Northrop Grumman Cygnus spacecraft carrying 8,200 pounds of food, fuel, supplies, and science and a Progress resupply spacecraft carrying three tonnes of cargo arrived at the station.

NASA has additional SpaceX resupply missions planned through the end of 2024.

–IANS

na/

Sci/tech

JNCASR, HZL pact paves way for advance energy storage solutions in India

New Delhi, Aug 22 (IANS) A recent Memorandum of Understanding (MoU) between Jawaharlal Nehru Centre for Advanced Scientific Research (JNCASR), an independent institution under the Department of Science and Technology (DST), and Hindustan Zinc Limited (HZL) marks a significant advancement in the development of energy storage solutions in India.

The partnership intends to expedite the commercialisation of zinc-ion batteries and create novel zinc material types.

Because of its greater performance and lower cost, zinc-ion batteries are becoming more and more popular as a viable replacement for the more expensive and foreign lithium-ion batteries.

Because of the abundance of zinc in the Earth’s crust and the material’s inherent safety, these batteries have the potential to have a big impact on the market due to their large-scale energy storage capabilities.

The promise for zinc-ion batteries to completely transform the energy storage industry has been reinforced by recent developments in material stability and performance over a wide temperature range.

The commercialisation of zinc-ion batteries is contingent upon the resolution of various obstacles, including the thermodynamic instability of zinc in solutions including water, notwithstanding their promising nature.

By creating novel zinc alloys for use as anodes and altered electrolytes to increase the longevity and safety of the batteries, JNCASR and HZL want to overcome these issues.

The JNCASR research group of Professor Premkumar Senguttuvan has established a solid framework for zinc-based battery research, producing noteworthy publications and piquing the interest of industrial players.

Through this agreement, scalable zinc-ion pouch batteries appropriate for large-scale commercial applications will be developed by utilising JNCASR’s research knowledge and HZL’s product creation skills.

This project represents a turning point in the development of battery technology as India transitions to a sustainable energy future.

It is in line with two important Sustainable Development Goals, SDGs 7 (Affordable and Clean Energy) and SDG 13 (Climate Action).

–IANS

ts/rad

Sci/tech

Beyond the smartphone: POCO Pad to usher in 5G phablet era

Mumbai, Aug 22 (IANS) Global smartphone brand POCO on Thursday said that drawing inspiration from the phablets that first blurred the lines between phone and tablet, its new Pad has gone a step further.

By harnessing the power of 5G and integrating it into a user experience designed for a generation that lives life on the go, POCO offers a glimpse into a future where seamless connectivity is the norm. This isn’t just about bigger screens; it’s about expanding the boundaries of how and where we interact with the digital world.

POCO Pad reimagines the phablet for today’s users. While phablets strived to remain pocketable, the POCO Pad embraces its tablet form factor, offering a truly expansive 12.1-inch canvas for work and play. It’s the perfect size for those who found phablets a tad too cramped but still crave a portable powerhouse.

Phablets were limited by the connectivity of their time. The POCO Pad harnesses the power of 5G, enabling lightning-fast downloads, seamless streaming, and lag-free video calls – activities that were often a pipe dream on earlier large-screen devices.

Phablets hinted at the potential for mobile productivity, but the POCO Pad delivers. Its powerful processor, long-lasting battery, and optional accessories like a keyboard make it a true productivity companion, whether you’re editing documents, creating presentations, or managing your busy schedule.

The POCO Pad transforms into a portable entertainment hub with a stunning 2.5K display, Dolby Atmos sound, and all-day battery life. Binge-watch your favorite shows, immerse yourself in games, or video chat with friends and family – all with a level of quality and immersion that phablets could only dream of.

The company said that POCO Pad offers a large screen, portability, and versatility – and elevates them to new heights with cutting-edge technology and a focus on delivering an exceptional user experience.

–IANS

avs/na

Sci/tech

Concerning spike in back and spine problems due to excessive gadget use: Doctors

New Delhi, Aug 22 (IANS) The excessive use of gadgets among individuals aged 20 to 55 is leading to a significant increase in back and spine problems, doctors warn.

Many are experiencing severe and debilitating symptoms, including sharp, stabbing, or dull pain in the back or neck, muscle spasms, tingling, loss of sensation, and even weakness or limited mobility.

Prolonged screen time is increasing musculoskeletal disorders, particularly affecting the spine, with severe pain, tingling, and functional weakness being reported.

“In this digital era, prolonged screen time is causing a rise in musculoskeletal disorders (MSD), particularly affecting the spine. There has been a 60 per cent surge in back and spine issues. Individuals aged 20-55 are reporting severe pain, sometimes accompanied by loss of urinary or bowel control, tingling in the extremities, and functional weakness. Seven in ten patients I see daily suffer from back and neck pain,” Mohit Muttha, Orthopaedic & Spine Surgeon at Apollo Spectra, Pune told IANS.

“Poor posture, especially forward head posture (FHP), due to excessive gadget use, leads to muscle imbalances and tightened hip flexors, making daily activities stressful and painful,” added Muttha.

“A 60 per cent increase in low back and neck issues among 20-45-year-olds is linked to gadget addiction, causing discomfort in the neck and cervical spine. If neglected, this can lead to more severe issues, including neck pain, shoulder stiffness, headaches, and restricted mobility. Out of 10-12 patients who visit me daily, around 4-5 have neck and lower back pain related to gadget misuse,” Ram Chaddha, Spine Surgeon at Lilavati Hospital, Mumbai told IANS.

Regular breaks, posture, and daily exercises like yoga and stretching are crucial for preventing back and spine issues among 20-50-year-olds.

“There is a concerning 50 per cent surge in back and spine issues among people aged 20-50. Out of five patients, at least 2-3 suffer from back pain and are advised to rest for prompt recovery,” Burhan Salim Siamwala, Consultant Spine Surgeon at Medicover Hospitals, Navi Mumbai told IANS.

–IANS

ts/svn

-

Video2 years ago

PM Modi Attacks Congress in Karnataka with “Kerala Story”

-

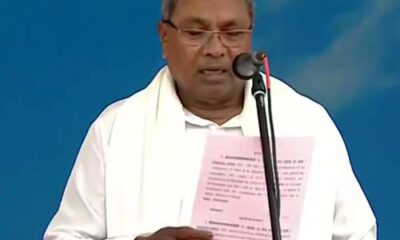

Politics2 years ago

Siddaramaiah & DK Shivakumar sworn in as Chief Minister & Deputy CM respectively

-

Cricket2 years ago

CSK players rejoice 5th IPL title with their families (Pics)

-

Entertainment2 years ago

Karan Deol weds his longtime Girlfriend Drisha Acharya (Pics)

-

Sports7 years ago

History Of Official FIFA WORLD CUP Match balls

-

India2 years ago

Ashwini Vaishnaw: Railway Board recommends CBI probe in the Odisha railway disaster

-

Entertainment2 years ago

Urvashi Rautela dazzles on Cannes 2023 red carpet (Pics)

-

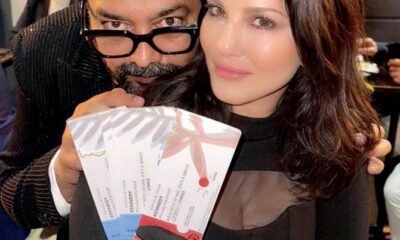

Entertainment2 years ago

Sunny Leone gets ready for Kennedy premiere in Cannes (Pics)